Here are 8 important tidbits of information about aluminum CNC machining that you need to know.

A popular saying paraphrased goes thus: You can never learn everything under the sun. The saying at its very core, means that at every point in time, there is always something new to learn about any field of endeavor – but it is perhaps most apparent when it comes to CNC machining.

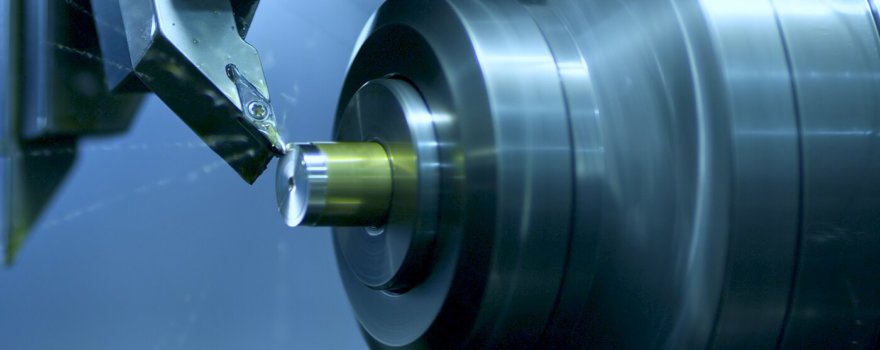

Aluminum CNC machining is the application of the metal aluminum as work material for CNC machining. CNC machining is short for “Computer Numerical Controlled” machining and this means carrying out fabrication processes such as cutting, molding, shaving and bending using machines that are controlled using computer inputs.

With that having been said, here are 8 things you should know about aluminum CNC machining:

- Aluminum is a common metal: Occurring naturally in almost all of the known habitable continents, aluminum is pretty common. This is why there isn’t a shortage of the metal despite demand for it having been rising steadily for decades now. It can be found in Africa, North and South America, Europe, Asia, and the Middle East.

- It is also the most commonly used metal for CNC machining: Aluminum as a metal has a combination of properties that make it almost a literal godsend when it comes to its applicability in CNC machining. It is light, resistant to rust, malleable, and durable and these make it the most sought after material by the aerospace, automotive, and consumer electronics industries.

- Aluminum has high potential for recycling: A very important benefit to aluminum is its great recycling potential. This is great for businesses that have a high priority of reducing their environmental footprint.

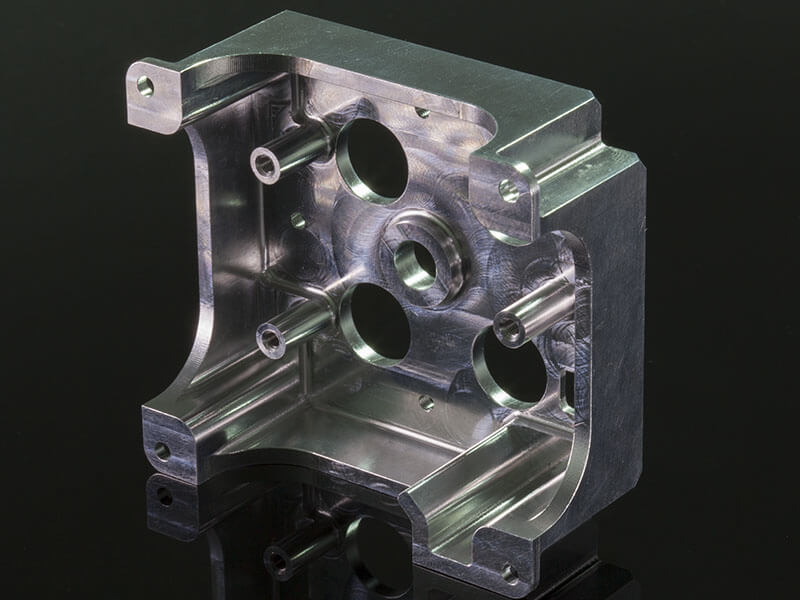

- Aluminum has a high strength to weight ratio: Few materials hit the sweet spot of being strong but also lightweight. This makes it such that it is highly workable but also, will not break apart when subjected to high pressure environments either during manufacturing or in use. This makes it extremely suitable for the manufacture of critical parts in crucial product industries such as automotive, aerospace, and heavy equipment parts manufacture.

- Aluminum is highly conductive (when you need it to be): High electrical conductivity: Due to its ability to conduct electricity, aluminum as a metal is excellent for manufacturing electrical parts. In its pure form, aluminum has an electrical conductivity of 37.7 million Siemens per meter (spr) at room temperature. This may place it lower than a material like copper, however, it still stands above other metals like stainless steel.

- It possesses high potential for anodization: Aluminum is greatly demanded for manufacturing especially in the consumer electronics industry. This is not just because of its excellent strength to weight ratio. It is also because of the metal can be treated with anodization. This process typically takes place after the machining process is completed and it usually involves passing an electric current through the component whilst it is places in a vat of electrolytic acid. The final product is a piece of aluminum that now is more resistant to rust as well as physical impact (to some degree).

- Aluminum is also a relatively cheap material – especially when compared to others like steel, silver, and copper. This means that is can easily be sourced in large quantities.

- It is projected that the demand for aluminum in the CNC machining will rist by a cumulative 30% over the next five years. This is due to an increase in demand for products in the industries that rely on aluminum as a raw material ie automotive, aerospace, and consumer electronics industries.

Finally, it cannot be overstated the importance of technical know-how. Always make sure to keep yourself engages with the regards to the goings on in the industry.

To read more on topics like this, check out the Technology Category.

Must Have Marketing Apps & Platforms for Realtors

Must Have Marketing Apps & Platforms for Realtors